Using recycled input

(A) Beginning-of-life: using recycled input (apparel/ built environment cross-industry case)

A recycling case: apparel waste becomes feedstock for floor tiles, with passports and cross-sector coordination making circular sourcing work.

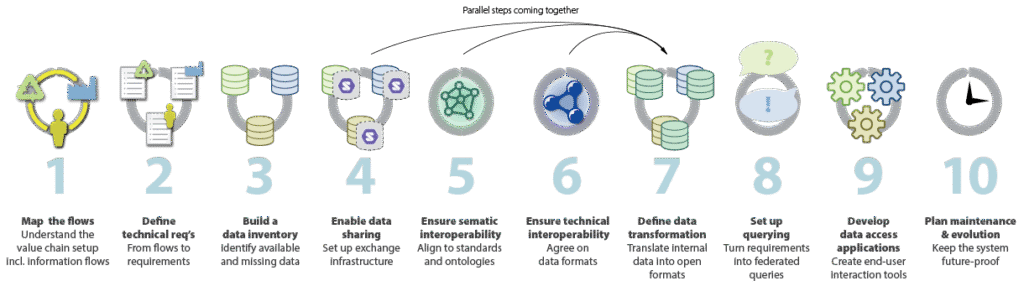

In this example case apparel waste turns into high-quality feedstock for acoustic floor tiles. It illustrates the process described in our two practical guides, specifically for recycling. Guide 1 Value chain design, development & innovation interrogates the circular value chain and how it functions—who’s involved, where value is lost, and which strategies unlock cross-sector flows. Guide 2 Decentralised data & information sharing then shows how product passports, governed disclosure, and interoperable data make batch selection and compliance verifiable. CEON and OCP refer to Onto-DESIDE’s Circular Economy Ontology Network and the Open Circularity Platform.

What: Cross-sector recycling of apparel waste into feedstock for floor tiles.

Why: To unlock circular business models and help to find the right recycled feedstock through product passports and secure data exchanges.

A product manufacturer creates a performance shoe using inputs from various material suppliers, each contributing data to a shared platform for product passports using standardized formats. Once the shoe reaches end-of-life, a recycling operator disassembles it, guided by digital instructions, and extracts the rubber outsoles and textile laces that are made into new bulk materials.

These recovered materials are listed on a digital marketplace, enriched with a certificate and metadata including composition, condition, and recycled content. Next, a materials processor identifies suitable batches and requests pricing via the platform. After purchase, the recycled inputs are turned into materials that an interior outfit company uses for acoustic floor tile layers. Certificates and material data travel along, and a new product passport is generated for the product.

Step 1—Current undermining tensions and desired patterns using the Multi-Flow Method

Individual vs. Collective Interest: Each actor optimizes for self-protection. Suppliers upload batch “proof” as PDFs with metadata at different levels of confidence and granularity (“rubber≈20%”), but keep sensitive fields—phthalates, heavy metals, formulations—offline. Recyclers list vague tags (“post-consumer, clean”); processors and buyers can’t verify claims such as “≤0.1% phthalates” or binder compatibility without seeing company secrets. Suppliers won’t risk exposure; buyers won’t risk non-compliance. Deals fail not for technical reasons, but because evidence can’t be shared selectively.

Improvement opportunity for data flows: Apply governed, selective disclosure. Certificates become machine-readable and are mapped to shared terms; sensitive results are issued as verifiable credentials with field-level, purpose-bound access and audit trails. A supplier can prove “Batch X meets limit Y” without revealing spectra or recipes. Predefined queries check compliance across decentralised stores, preserving ownership. With accountable, granular sharing, trust rises and qualified recycled batches can flow—opening trade across sectors. It is decided to create this.

Step 2 & 3—Requirements & Data Inventory

On a digital marketplace, the interior outfitter struggles to source recycled materials because the materials processor’s data is inaccurate and inconsistent. Certificates arrive as PDFs and spreadsheets with varying terms. The actors first meet to clarify their needs, writing user stories that specify which data is needed, in which situation, and for what purpose.

The materials processor’s data steward then builds a data inventory, cataloguing existing data, formats, ownership, gaps, and sensitivity. Most certificates list recycled content and composition; few include verified environmental impact scores. Toxic substance data is highly sensitive and only shared with trusted partners. A mitigation is to share thresholds only (as in REACH) and apply granular access restrictions.

Step 4—Enable Data Sharing

The data steward and marketplace developer enable data sharing by adopting a decentralised setup with Solid pods,based on the Open Circularity Platform (OCP), giving suppliers control over sensitive data. Fields needing protection get access rules. The processor subscribes to a hosted Solid service, configures access-controlled data fields, and registers its pod on the marketplace.

Step 5a—Ontology Requirements & Inventory

To improve the marketplace’s data infrastructure, the data steward and developer define Competency Questions (CQs): ‘What is the recycled content?’ and ‘Are toxic substances below legal limits?’ The CQs are mapped to Onto-DESIDE’s CEON ontology. CEON covers broad concepts (e.g., ‘Material,’ ‘Composition’) but lacks terms for recycled footwear components and batch-level certification metadata. The developer records which CQs are supported and which require extensions, laying the groundwork to refine the ontology around real data needs.

Step 5b—Ontology Extension

To describe recycled shoe rubber accurately, the developer reused CEON and extends it by adding a subclass RecycledFootwearRubber under Material, and a property hasBatchCertificate to link materials to compliance data. The extension is then verified with the data stewards and end user representatives. This allows detailed descriptions of batches, such as “contains 22% recycled rubber, certified below legal thresholds for phthalates.” These extensions ensure semantic clarity and support traceability across systems, enabling consistent data interpretation and reuse.

Step 6—Ensure Technical Interoperability

The suppliers store their data in formats like CSV and JSON, which vary in structure. To standardize this, the developer proposes to convert this data into RDF, linking each field—such as rubber content or batch ID—to the extended CEON concepts. This ensures that all actors interpret the data consistently, enabling smooth exchange and integration across the digital marketplace.

Step 7—Define Data Transformation

Using YARRRML mapping files, the developer describes how CSV headers and JSON keys from the suppliers’ source data—such as “rubber_content” and“certificate_id”—map to CEON properties like MatterComposition and hasBatchCertificate. Sensitive fields, such as toxic substance levels, get restricted access. Lastly, all the data is uploaded to the Solid pods of the suppliers.

Step 8—Set Up Querying

To retrieve relevant information, the developer creates SPARQL queries, to be executed over the OCP. One query asks: “Which batches contain recycled rubber certified below legal thresholds for phthalates?” These queries run across all decentralised Solid pods, allowing processors and buyers to verify compliance and material suitability.

Step 9–Develop Data Access Applications

The developers of the materials marketplace edit their dashboard to browse available batches of recycled rubber based on the new terms of the extended CEON vocabulary. This app connects to the OCP, consisting of the published Solid pods, and runs the predefined SPARQL queries to retrieve batch composition, recycled content, and certification status. Sensitive data, such as exact toxic substance levels, is only shown to specific authorized users. The interface allows filtering by material type and compliance status, supporting informed procurement decisions and enabling traceable, circular sourcing.

Step 10–Plan Maintenance and Evolution

As new suppliers join the marketplace or regulations change, the data steward and the developers update the data inventory, ontology, YARRRML mapping files and SPARQL queries. As the system was designed to accommodate new actors and data sources this does not disrupt existing workflows, and long-term adaptability and compliance in the circular value chain is ensured.

Curious how strategy becomes operations? Dive into the guides for the full process, see the “Tools & Training” section.