In a circular economy resources and value need to flow frictionless between partners, both within and across value chains. Data and information needs to flow just as freely – but at the same time keep what matters safe, such as sensitive company information.

But right now it’s hard to understand how these flows combine to drive a circular value chain forward. And: data sharing is often impractical, time-consuming, and expensive. So how can these problems be solved?

Onto-DESIDE addresses these core obstacles for industry, through:

These solutions were developed through industry use cases with various sections, demonstrating and quantifying the potential for increased retainment of value.

Cellulose fibres are recycled into components for high-performance shoes

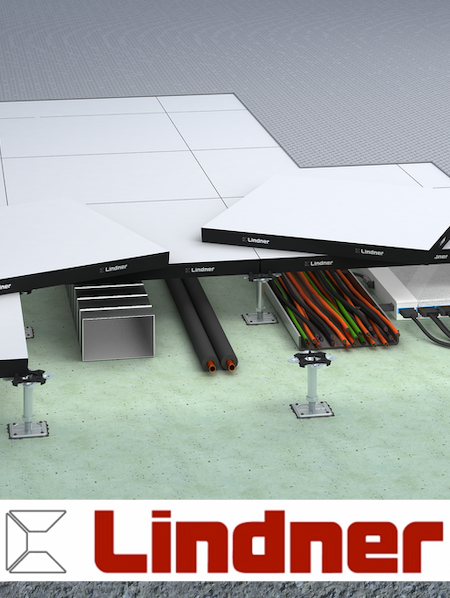

Developing a take-back system for floor tile refurbishment and remanufacturing

Rare earth elements in speaker magnets need to be traced and retrieved at end of life

In this example apparel waste becomes feedstock for the acoustic underlayer of floor tiles, with passports and cross-sector coordination making circular sourcing work.

Repair comes to outperform replacement: a malfunctioning audio system restored with parts and instructions; and data sharing automates digital twin updates.

Explore a reuse case: doors listed with passports and access-controlled terms, linking sellers and builders to match fit, code, and price.

Follow a take-back case: floor tiles returned to manufacturer via data and logistics, enabling predictable remanufacturing and securing future feedstock.